Digital Twin for Airline Operations & Supply Chain

Implemented a digital twin of airline operations spanning flight schedule, turnaround, ground handling, crew and maintenance constraints, enabling rapid scenario modelling and reducing disruption response time by ~35%.

Project Goals

- Create a near-real-time digital twin of the airline’s operational network: flights, aircraft rotations, gates/stands, turnaround activities, crew pairings, baggage flows, and key maintenance constraints.

- Provide dispatch, OCC, and station managers with scenario modelling for common disruption patterns (weather, ATC flow restrictions, late inbound, equipment swap, gate unavailability, crew legality).

- Improve cross-team alignment by giving ground ops, engineering, and network control a shared “single operational picture” with consistent KPIs and definitions.

- Reduce reliance on ad-hoc spreadsheets by introducing repeatable, auditable playbooks for disruption response.

- Deliver measurable improvements in on-time performance drivers: turnaround adherence, misconnects, baggage performance, and aircraft utilisation recovery.

Process & Implementation

Discovery & Operating Model

Mapped the airline’s day-of-ops processes across OCC/IOCC, station operations, maintenance control, and ground handlers.

Defined the “twin boundary”: what must be modelled in real time (constraints, states, and events) vs what remains reference/master data.

Data Integration & Event Model

Integrated operational sources typically found in airlines, including:

- Flight schedules and rotations

- Aircraft status and tech logs

- Turnaround milestones & A-CDM timestamps

- Crew pairing/rostering and legality

- Baggage sortation and load messaging

- Weather and flow program advisories

Implemented an event-driven model to maintain an always-current operational state, with late/duplicate event handling and reconciliation rules.

Digital Twin & Scenario Engine

Built a constraint-aware twin capable of simulating:

- Aircraft swaps and knock-on effects

- Gate/stand reassignment implications

- Turnaround time compression/extension

- Crew connection risk and recovery options

- Maintenance windows and deferral impacts

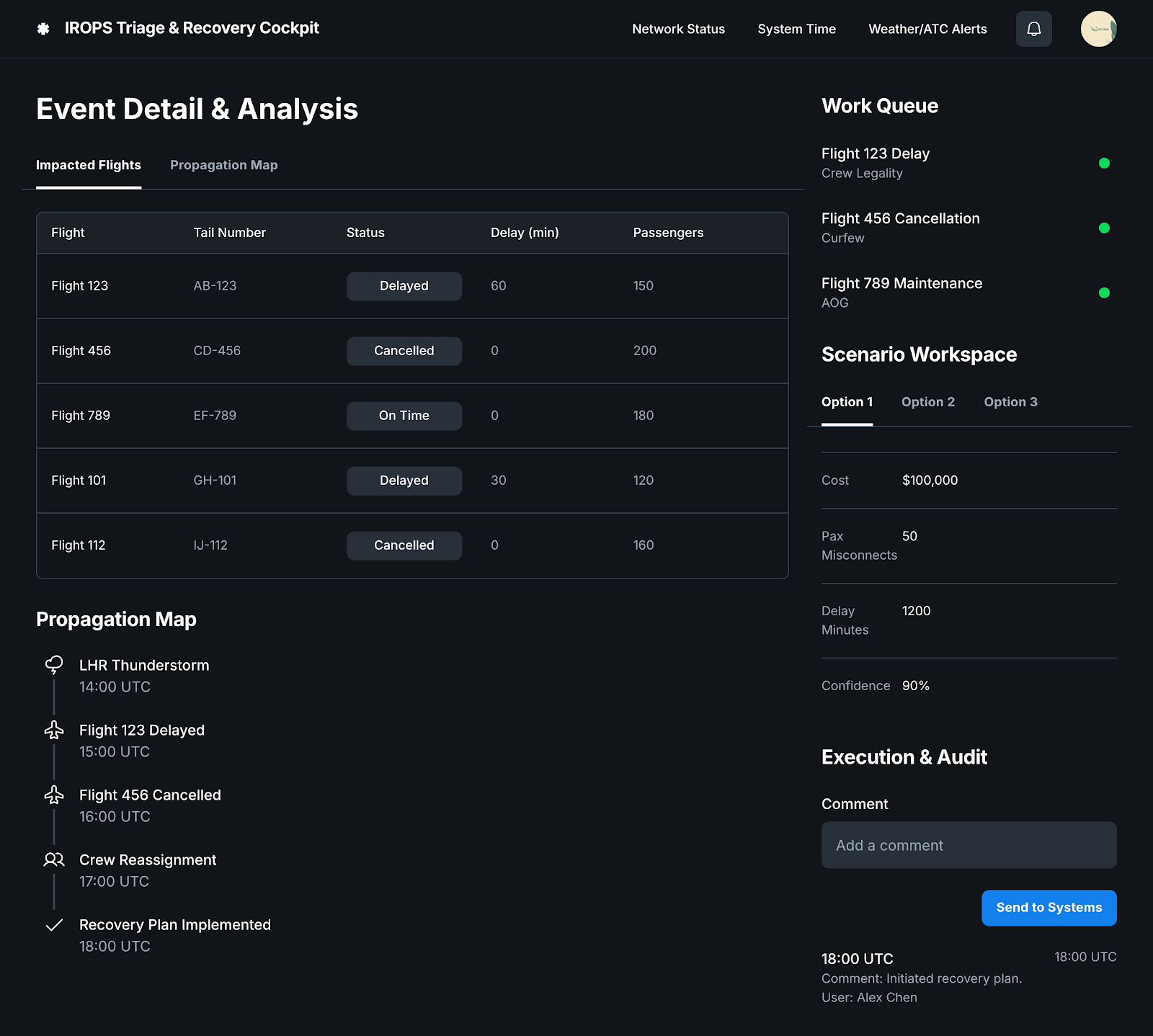

Added “what-if” templates for the most frequent disruptions: late inbound, curfew risk, severe weather, gate holds, and equipment constraints.

User Experience & Adoption

Delivered a role-based web dashboard with:

- Network view (risk heatmap and recovery options)

- Station view (turnaround health, resource bottlenecks)

- “Playbook” actions with assumptions visible (not black box)

Ran structured training for OCC controllers and station leads and introduced a lightweight governance process for KPI definitions and scenario templates.

Results & Impact

~35% Faster Disruption Response

Time from alert to agreed recovery plan was significantly reduced by using pre-built scenarios and a shared operational picture.

Reduced Cascade Delays

Earlier identification of high-risk rotations and proactive equipment swaps on peak days minimized knock-on effects.

Improved Turnaround Predictability

Measurable uplift in milestone adherence at the highest-volume stations after rollout of station-level dashboards.

Unified Status & Definitions

Fewer manual handoffs between OCC, ground handling, and maintenance control through unified status and consistent definitions of “ready” states.

Foundation for Ongoing Optimisation

The airline can add new scenario templates (e.g., de-icing constraints, seasonal schedule peaks) without re-architecting the twin, enabling continuous improvement.